In industry, CNC machines used during the manufacture of enclosures may include injection-moulding machines, lathes, drills and integrated machining centres, which can carry out both milling and drilling.

Honyo prototype has equipped with 150+ strong CNC machines with biggest machining stroke at 2500*850mm, offering the full range of cnc milling processes, drilling, boring, countersinking, counter boring, tapping, and reaming, plus more. When the time comes if you need milling done, however you need it done, we can do it. Taking on both small and large jobs, with fully enabled Multi-Axis machining especially 5-axis cnc machining, cutting to manufacture a wide range of intricate components-nothing is too complex for us. In our shop precision is the number one goal. We work to tolerances as tight as ± 0.002 per inch of dimension although tighter tolerances are possible with very stable, reinforced materials.

Sometimes the cnc machining price can be cheaper than even rapid prototyping additive manufacturing depending on the geometry. We have helped product design engineers and professionals with their projects across a wide range of industries, and we can help you.

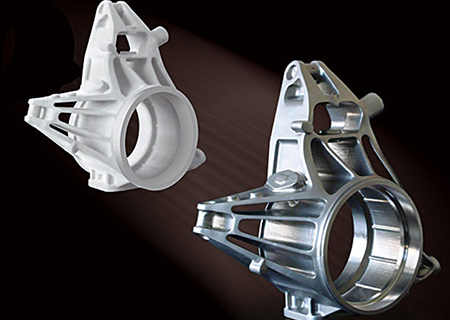

Precision machining-machine tools is one of the best choices for prototype and pre-production of high-quality metal and plastic parts requiring the greatest degree of dimensional accuracy, critical surface finishes, polished fabrication, and material specific properties for parts that are too large for the additive prototyping processes.

Commonly requested materials are:

| ● ABS ● Polycarbonate ● PC/ABS ● Teflon ● Nylon ● PEEK ● Ultem ● Aluminum ● Brass ● Copper ● Delrin ● Magnesium ● Mild Steel ● Nylon ● PMMA (Acrylic) ● Stainless Steel |